In industries where equipment is exposed to extreme abrasion, impact, and wear, finding the right material to protect your machinery is crucial. Chromium Carbide Steel Plate has emerged as a top choice for engineers and manufacturers seeking a durable, long-lasting solution. With its exceptional hardness and wear resistance, this advanced material is revolutionizing the way industries tackle wear-related challenges. Let’s explore what makes chromium carbide steel plate a game-changer.

What is Chromium Carbide Steel Plate?

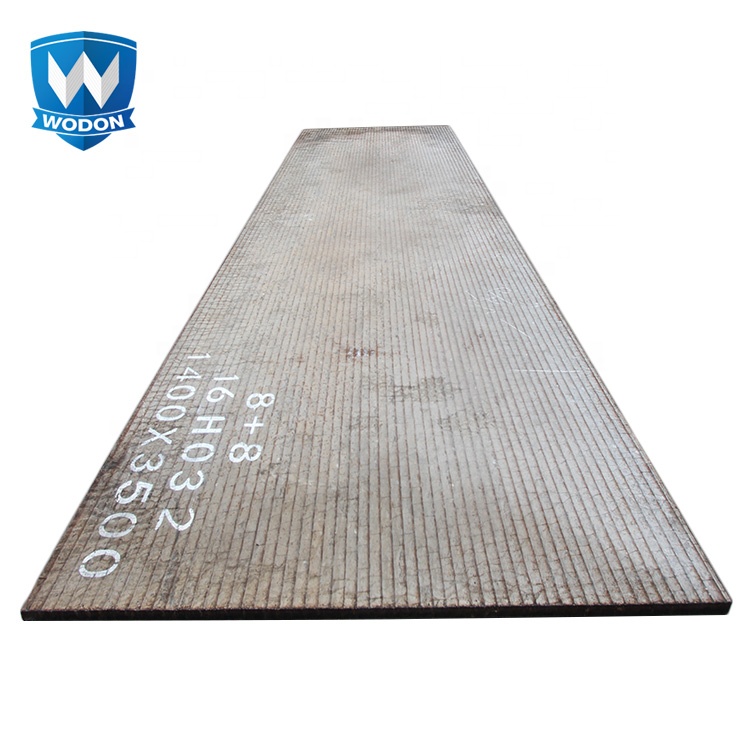

Chromium carbide steel plate is a composite material made by overlaying a steel base plate with a layer of chromium carbide. This overlay is applied using advanced welding techniques, such as flux-cored arc welding (FCAW) or submerged arc welding (SAW), to create a hard, wear-resistant surface. The result is a plate that combines the toughness of steel with the extreme hardness of chromium carbide.

Key Features of Chromium Carbide Steel Plate

Exceptional Hardness

The chromium carbide overlay provides a hardness of 60-65 HRC (Rockwell Hardness), making it one of the hardest materials available for wear protection.

Superior Wear Resistance

Chromium carbide steel plates are designed to withstand severe abrasion, making them ideal for applications involving sliding, scraping, or impact wear.

Impact Toughness

Unlike brittle ceramics or other hard materials, chromium carbide steel plates offer excellent impact resistance, ensuring they can handle heavy loads without cracking.

Corrosion Resistance

The chromium content in the overlay provides additional protection against corrosion, making it suitable for harsh environments.

Customizable Thickness

The thickness of the chromium carbide overlay can be tailored to meet specific application requirements, ensuring optimal performance and cost-effectiveness.

Applications of Chromium Carbide Steel Plate

Chromium carbide steel plates are widely used in industries where wear and tear are major concerns. Some common applications include:

Mining Equipment: Protects chutes, hoppers, and conveyor systems from abrasive materials like ore and rock.

Cement Industry: Used in crushers, grinders, and kiln feed chutes to resist wear caused by clinker and raw materials.

Power Generation: Shields coal handling equipment, such as pulverizers and ash conveyors, from abrasion and erosion.

Steel Manufacturing: Protects blast furnace equipment, rolling mills, and slag handling systems.

Recycling Industry: Ideal for shredders, crushers, and sorting equipment exposed to abrasive materials.

Advantages of Using Chromium Carbide Steel Plate

Extended Equipment Life

By reducing wear and tear, chromium carbide steel plates significantly extend the lifespan of industrial equipment.

Reduced Downtime

The durability of these plates minimizes the need for frequent replacements and repairs, leading to less downtime and higher productivity.

Cost-Effective Solution

Although the initial investment may be higher, the long-term savings in maintenance and replacement costs make it a cost-effective choice.

Versatility

Suitable for a wide range of industries and applications, chromium carbide steel plates offer a versatile solution for wear protection.

Why Choose Wodon Chromium Carbide Steel Plates?

At Wodon Wear-Resistant Materials Co., Ltd., we specialize in producing high-quality chromium carbide steel plates that meet the highest industry standards. Our plates are manufactured using state-of-the-art technology and rigorously tested to ensure they deliver unmatched performance in the most demanding environments.

Get in Touch Today!

If you’re looking for a reliable, long-lasting solution to combat wear and extend the life of your equipment, Wodon Chromium Carbide Steel Plates are the answer. Contact us today to learn more about our products or to request a customized solution for your specific needs.

Name:Mrs.Zhang

Phone:+86 13115230820

Tel:+86 13115230820

E-mail :[email protected]

Add:No. 11 Jinji Road, Hongze Economic Development Zone, Huai'an City, Jiangsu Province, China